Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Новости

Новости

How to Choose a Wire Straightening and Cutting Machine Supplier

How to Choose a Wire Straightening and Cutting Machine Supplier

Whether you're a construction company looking to streamline your wire cutting and straightening processes, or a manufacturer in need of high-quality wire products, finding the right supplier is key to your success. So, let's dive in and discover how you can find the perfect wire straightening and cutting machine supplier to meet your specific requirements.

Factors to Consider When Choosing a Supplier

When it comes to finding a wire straightening and cutting machine supplier, there are several factors to consider in order to make an informed decision. Here are some key points to keep in mind:

Quality and Reliability: Look for a supplier that has a reputation for providing high-quality machines that are reliable and durable. Check for certifications and customer reviews to ensure their products meet industry standards.

Experience and Expertise: Consider suppliers with extensive experience in the field of wire straightening and cutting machines. Look for companies that have been in business for a significant amount of time and have a proven track record of delivering quality products.

Customization Options: Depending on your specific requirements, you may need a supplier that can offer customization options for the machines. Look for suppliers that can tailor their products to meet your unique needs.

After-Sales Support: It is important to choose a supplier that provides excellent after-sales support. This includes technical assistance, maintenance services, and readily available spare parts. A reliable supplier should be able to offer prompt and efficient support whenever needed.

Price and Value for Money: While price is an important consideration, it should not be the sole determining factor. Look for suppliers that offer competitive pricing while still delivering value for money. Consider the overall quality, performance, and after-sales support when evaluating the price.

Delivery Time and Logistics: Check the supplier's delivery timeframes and their ability to meet your deadlines. Consider their logistics capabilities to ensure timely delivery of the machines.

By considering these factors, you can find a reliable wire straightening and cutting machine supplier that meets your specific needs and provides quality products and services.

Researching Potential Suppliers

When it comes to finding a reliable wire straightening and cutting machine supplier, thorough research is essential. Here are some key steps to take when researching potential suppliers:

Online Search: Begin by conducting an online search to identify suppliers that specialize in wire straightening and cutting machines. Look for suppliers in facebook,Jcxlc.com or google search engine, informative websites, and positive customer reviews.

Industry Networks: Tap into industry networks, forums, and associations to gather recommendations and insights from professionals in the field. These networks can provide valuable information about reputable suppliers and their track records.

Trade Shows and Exhibitions: Attend trade shows and exhibitions related to the wire straightening and cutting machine industry. These events offer an opportunity to meet suppliers in person, see their products firsthand, and engage in meaningful discussions.

Request for Information: Reach out to potential suppliers and request detailed information about their products, manufacturing processes, quality control measures, and certifications. This will help you assess their capabilities and determine if they meet your specific requirements.

Customer References: Ask potential suppliers for customer references or case studies. Contact these references to gain insights into their experience with the supplier, including product quality, delivery times, and after-sales support.

Evaluating Supplier Credentials and Experience

When it comes to finding a reliable wire straightening and cutting machine supplier, evaluating their credentials and experience is crucial. This step ensures that you are partnering with a reputable and knowledgeable supplier who can meet your specific needs. Here are some factors to consider when evaluating supplier credentials and experience:

Industry Reputation: Research the supplier's reputation in the industry. Look for customer reviews, testimonials, and ratings to get an idea of their track record and customer satisfaction.

Years of Experience: Consider the supplier's experience in the industry. A supplier with extensive experience is more likely to have a deep understanding of wire straightening and cutting machines and can provide valuable insights and recommendations.

Certifications and Accreditations: Check if the supplier holds any relevant certifications or accreditations. This demonstrates their commitment to quality and adherence to industry standards.

Technical Expertise: Evaluate the supplier's technical expertise in wire straightening and cutting machines. Look for evidence of their knowledge and proficiency in the field, such as patents, research papers, or industry awards.

Customer Support: Assess the supplier's customer support capabilities. Do they offer timely and responsive assistance? Can they provide technical support, troubleshooting, and spare parts when needed?

References and Case Studies: Request references from the supplier and ask for case studies or examples of their previous work. This will give you an idea of their past projects and their ability to meet specific requirements.

By thoroughly evaluating a supplier's credentials and experience, you can make an informed decision and choose a reliable partner for your wire straightening and cutting machine needs. Remember to prioritize quality, expertise, and customer support to ensure a successful partnership.

Comparing Prices and Negotiating Contracts

When it comes to finding a wire straightening and cutting machine supplier, one crucial aspect to consider is the price. Comparing prices from different suppliers will help you find the best deal while staying within your budget. However, it's important to remember that price should not be the sole determining factor. Quality, reliability, and after-sales support are equally important.

To compare prices effectively, request quotes from multiple suppliers and carefully review the details of each offer. Look for any hidden costs or additional fees that may affect the overall price. It's also essential to consider the reputation and track record of the supplier. A lower price may not always guarantee the best value if the supplier has a history of poor quality or unreliable service.

Once you have narrowed down your options, it's time to negotiate the contract. Negotiating with the supplier can help you secure a better price or additional benefits. Be prepared to discuss your specific requirements, volume of orders, and any potential long-term partnership opportunities. Remember to be respectful and professional during negotiations, as building a positive relationship with the supplier is crucial for future collaborations.

During the negotiation process, pay attention to the terms and conditions of the contract. Ensure that all important aspects, such as delivery schedules, warranty, and payment terms, are clearly defined and agreed upon. It's also advisable to seek legal advice or involve a contract specialist to ensure that the contract protects your interests.

By comparing prices and negotiating contracts effectively, you can find a wire straightening and cutting machine supplier that not only offers competitive pricing but also meets your quality and service requirements.

Ensuring Timely Delivery and After-Sales Support

When it comes to purchasing wire straightening and cutting machines, ensuring timely delivery and reliable after-sales support is crucial. Here are some tips to help you choose a supplier who can meet these requirements.

Delivery Time: Inquire about the supplier's average delivery time for the machines. Look for suppliers who have a track record of delivering products on time. This will ensure that you can start using the machine as planned and avoid unnecessary delays in your operations.

Shipping Options: Ask the supplier about their shipping options and whether they provide tracking information. Having visibility into the shipping process allows you to plan for the arrival of the machine and ensure its safe delivery.

Warranty and Service: Check the warranty period offered by the supplier and the extent of after-sales support they provide. A reputable supplier will offer a warranty that covers any manufacturing defects and provide prompt assistance in case of any issues or breakdowns.

Technical Support: Inquire about the availability of technical support from the supplier. This could include assistance with installation, training, and troubleshooting. Having reliable technical support ensures that you can quickly resolve any operational issues and maximize the efficiency of the machine.

Spare Parts Availability: Find out if the supplier stocks spare parts for the wire straightening and cutting machines. This will ensure that you can easily replace any worn-out or damaged parts and minimize downtime.

By considering these factors, you can choose a supplier who not only delivers the machine on time but also provides the necessary support to ensure its smooth operation. Finally,Don't forget to get a best price for your order.

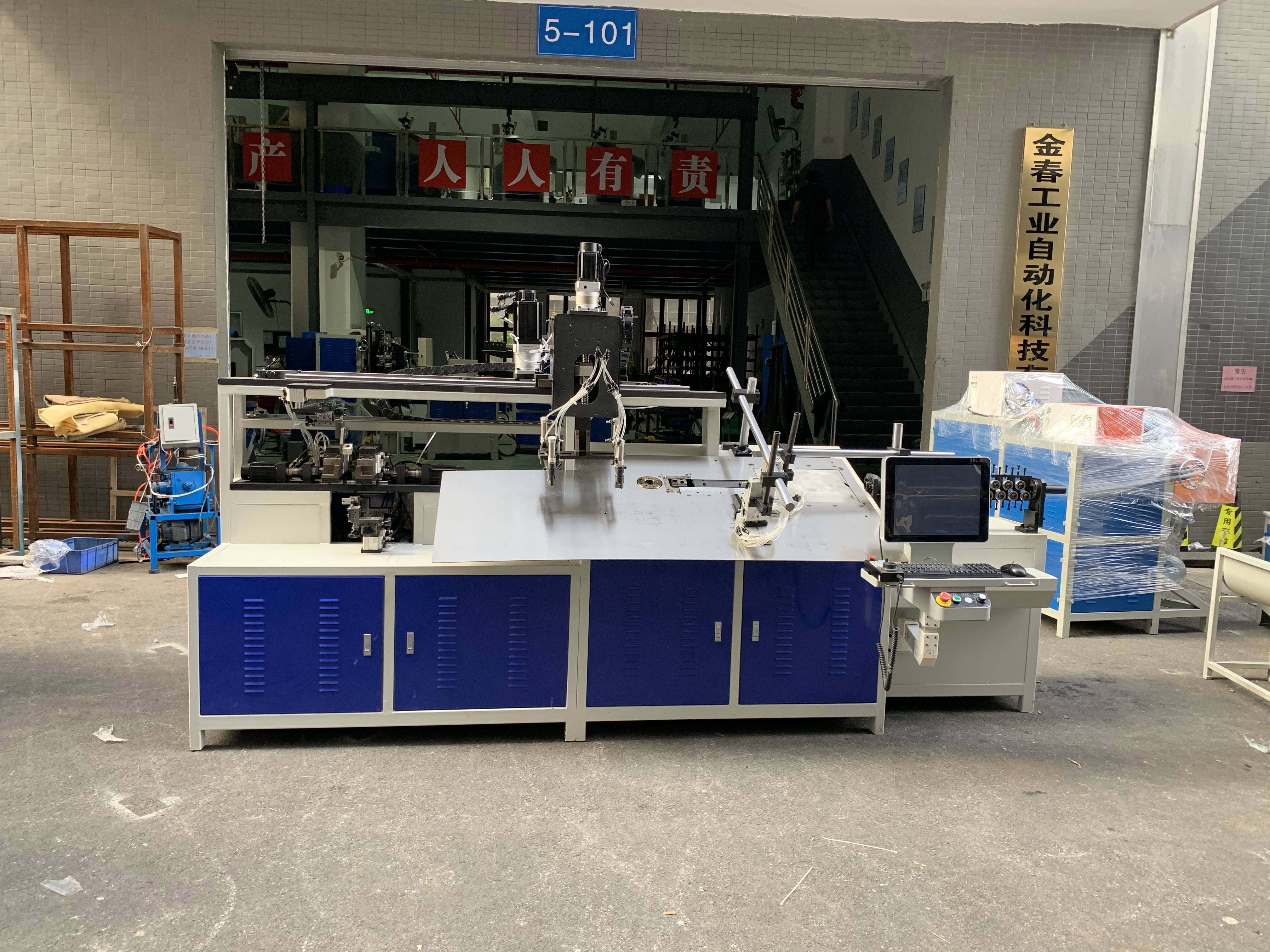

If you interest in these cnc wire straightening and cutting machine,please contact us asap.